PREMIUM

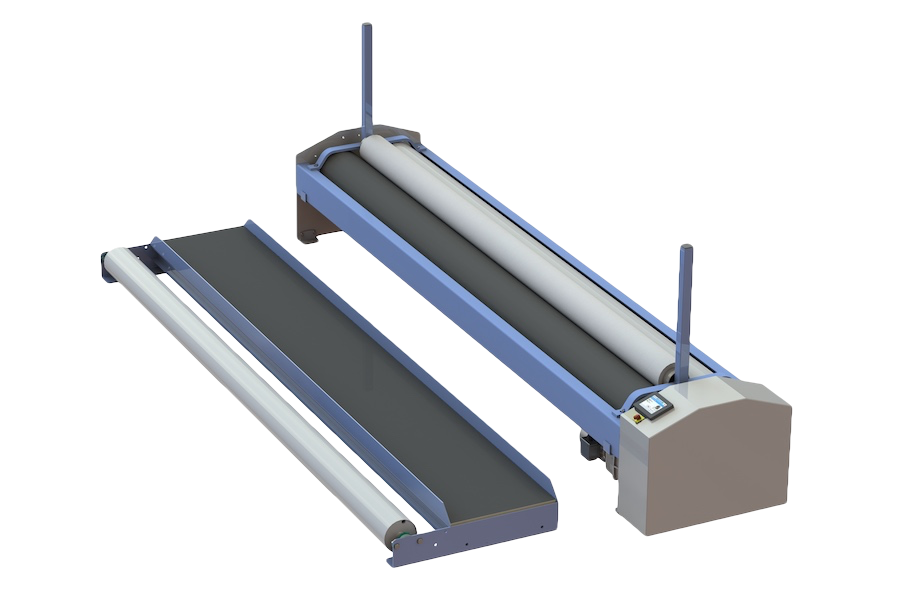

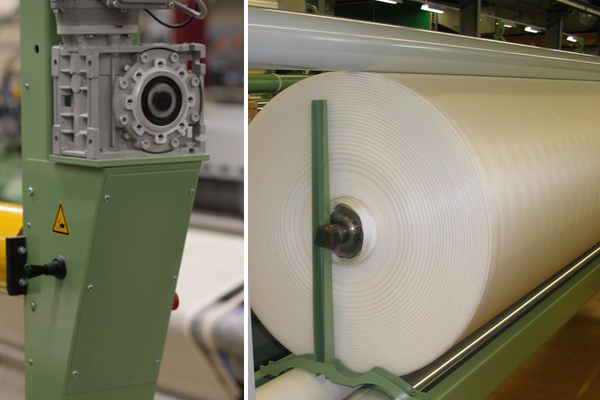

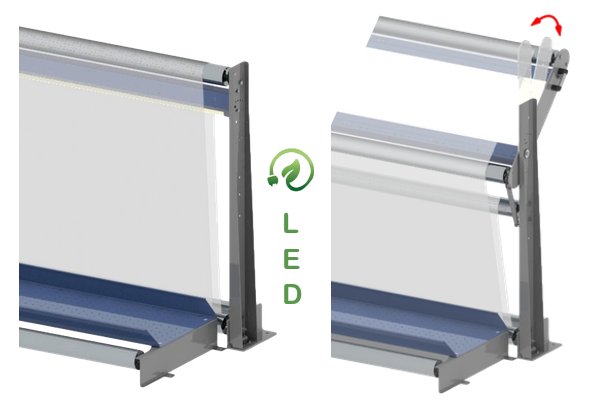

The Willy GROB batching unit type PREMIUM has been specially designed for applications on EXTRAWIDE weaving machines – e.g. particularly for nominal widths of 400cm to 540cm. Typical fields of application are geotextiles, polypropylene fabrics, trampoline-cloths and many more.

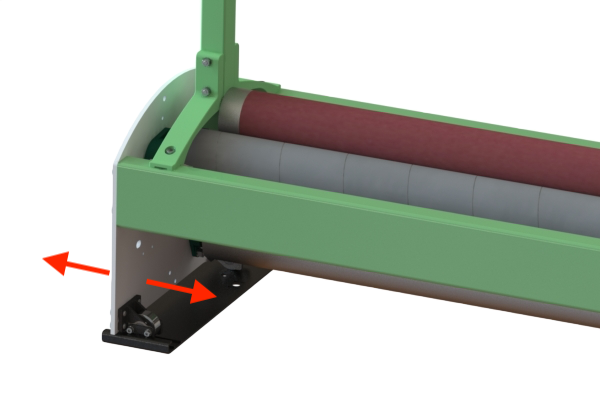

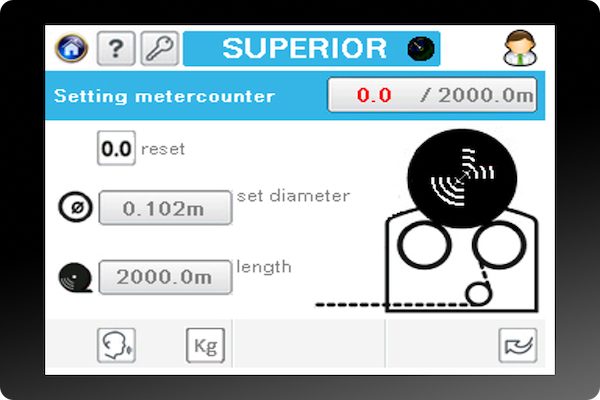

The fabric tension is directly measured and supervised with a state-of-the-art load cell. Deviations of the digital pre-setting are immediately detected. The system reacts instantly and assures a constant fabric tension from empty to full batch.

Heart of the system is the color-touch-screen panel using a fully graphic lead communication structure, allowing each and every user a friendly and intuitive handling in many different languages.

PDF-Download

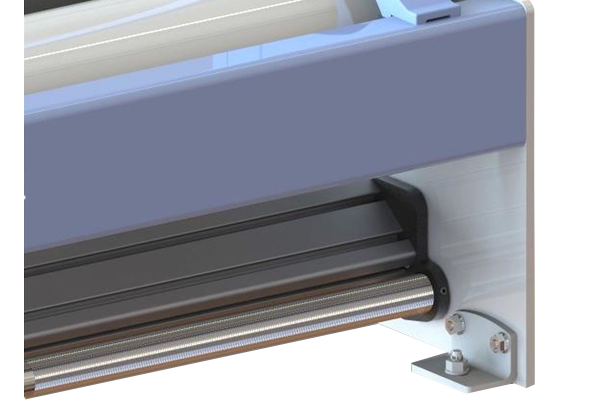

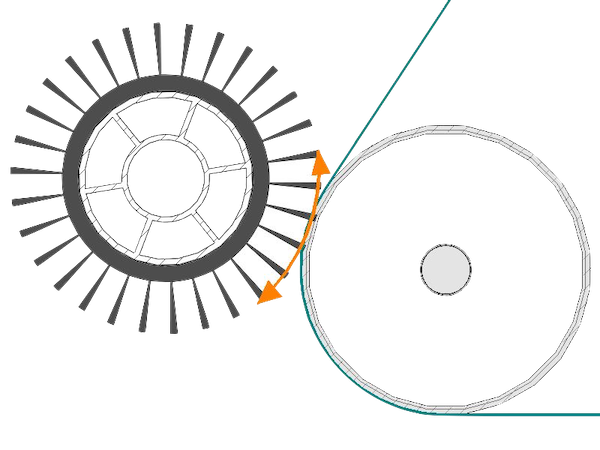

With this additional option, the surface of technical fabrics can be roughened in various intensities. The operation and adjustment is done by touch-screen panel ...

With this additional option, the surface of technical fabrics can be roughened in various intensities. The operation and adjustment is done by touch-screen panel ...